Lab Testing of GUV Products Reveals Accurate Performance Data Needed

Education and Industry-Standard Test Methods Needed to Improve Performance Claims

To perform testing, they used CALiPER, a product evaluation and reporting program launched by DOE in 2006 to address a need for unbiased, trusted performance evaluations for the LED lighting products that were entering the market.

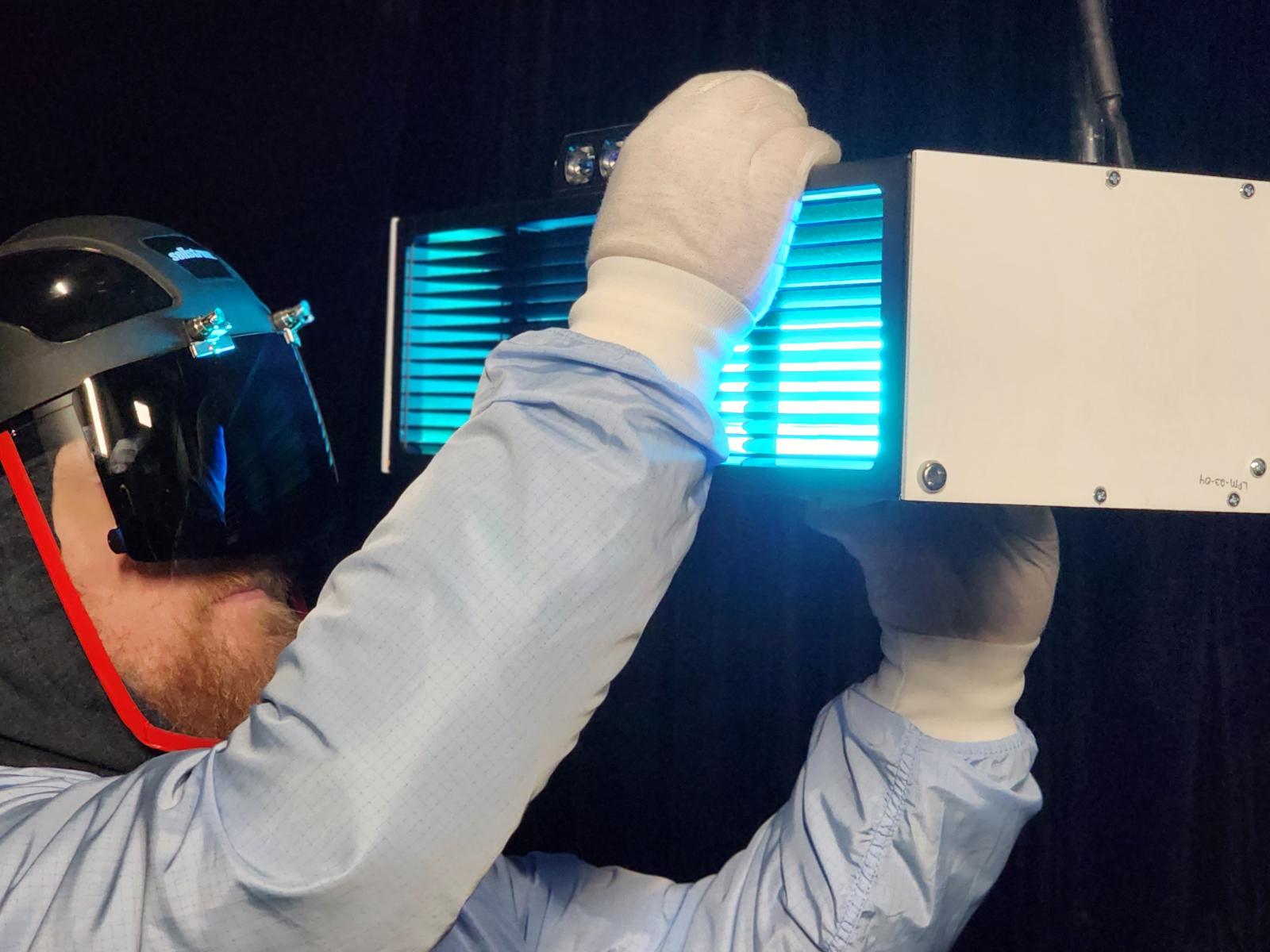

(Photo: LightLab International Allentown)

Lighting researchers at Pacific Northwest National Laboratory (PNNL) have been testing germicidal ultraviolet (GUV) lamps and luminaires with some surprising results. They put several off-the-shelf GUV products to the test and found substantial energy efficiency opportunities, but also questionable claims in their performance.

In their published reports, researchers Jason Tuenge, Gabe Arnold, Margaret Axelson, and Jianchuan Tan, observed that product ratings were often absent or inaccurate.

Well-designed GUV systems use ultraviolet-C (UV-C) energy to safely disinfect air. The technology promises to improve public health by reducing the transmission of airborne disease with minimal energy use. A related study recently published by PNNL (which simulated an office building in Chicago, IL, for one year) showed that supplementing ventilation with in-room GUV would use nearly 80% less energy than HVAC-only approaches to achieve guidelines recommended by the Centers for Disease Control and Prevention (CDC).

Due to its effectiveness and energy efficiency performance, GUV disinfection is expected to play an important role in meeting new building design guidelines by ASHRAE and the CDC. But fulfilling that promise depends on having commercially available products with accurate performance data.

The issue is that some manufacturers are uninformed about how to test and report product performance data, and industry-accepted standards for producing this data are only beginning to emerge.

Report shows discrepancies between claims and test results

Low-pressure mercury (LPM) has been widely used in health and institutional settings for decades. But newer technologies—like UV-C-emitting LEDs or krypton-chloride (KrCl) excimer lamps—began cropping up to satisfy an increased demand in disinfection technologies.

“During the pandemic there were many companies that came out with GUV disinfecting products that were producing UV and making all sorts of claims on performance,” said Gabe Arnold, program manager on this research; “we expected there to be some inaccuracies in terms of what some products were claiming, but in some instances, we found products emitting higher levels of UV-C than what was listed in the product specifications or even emitting no UV-C at all.”

The user manual for one LED tower warned users to stay at least one meter away, but testing standards indicate more than 2.5 hours of exposure to the product at that distance could be unsafe. The same product was found to emit UV-C before it was switched on using its remote control.

There were also concerns regarding long-term performance. For example, the UV-C output from two LED products decreased by 15–34% after 500 hours in use, even though both products had implied lifetimes of more than 8,000 hours.

Arnold emphasized that these findings are not indicative of all GUV products. In this initial round, 7 of the 13 different products tested were consumer products from online retailers, rather than the types of products that would normally be installed in a commercial building by a trained professional.

“Nevertheless, it’s something we need to address because it will only take a few bad apples installing this technology incorrectly or unsafely to tarnish the industry as a whole,” said Arnold.

Findings underscore need for GUV-specific testing methods and equipment

But perhaps most importantly, the researchers also observed several limitations with testing. PNNL researchers found variances in performance data depending on the testing equipment used.

“Without standardized testing methods and equipment that the full GUV industry is subscribed to, the industry will not be able to adequately market these products to buyers,” said the report’s lead author, Jason Tuenge. “We want to take what we learn and collaborate with industry to address some of the testing challenges and see all GUV product manufacturers reporting complete and accurate performance data.”

To perform testing, they used CALiPER, a product evaluation and reporting program launched by the U.S. Department of Energy in 2006 to address a need for unbiased, trusted performance evaluations for the LED lighting products that were just beginning to enter the market. Download the summary report to read about the Round 1 test results and recommendations, or the full report for more detailed discussion of the tested products, methods, and results.

Forthcoming publications will report results from three additional rounds of CALiPER GUV testing: upper-room luminaires, whole-room luminaires, and “round-robin” interlaboratory comparison testing. In addition to product testing, Arnold, Tuenge, and other PNNL team members are currently working on several field validation projects with the objective of gathering real-world data on the application and energy savings potential for GUV technology.

Published: April 4, 2024