PNNL Advances May Make for Better Family Vacations

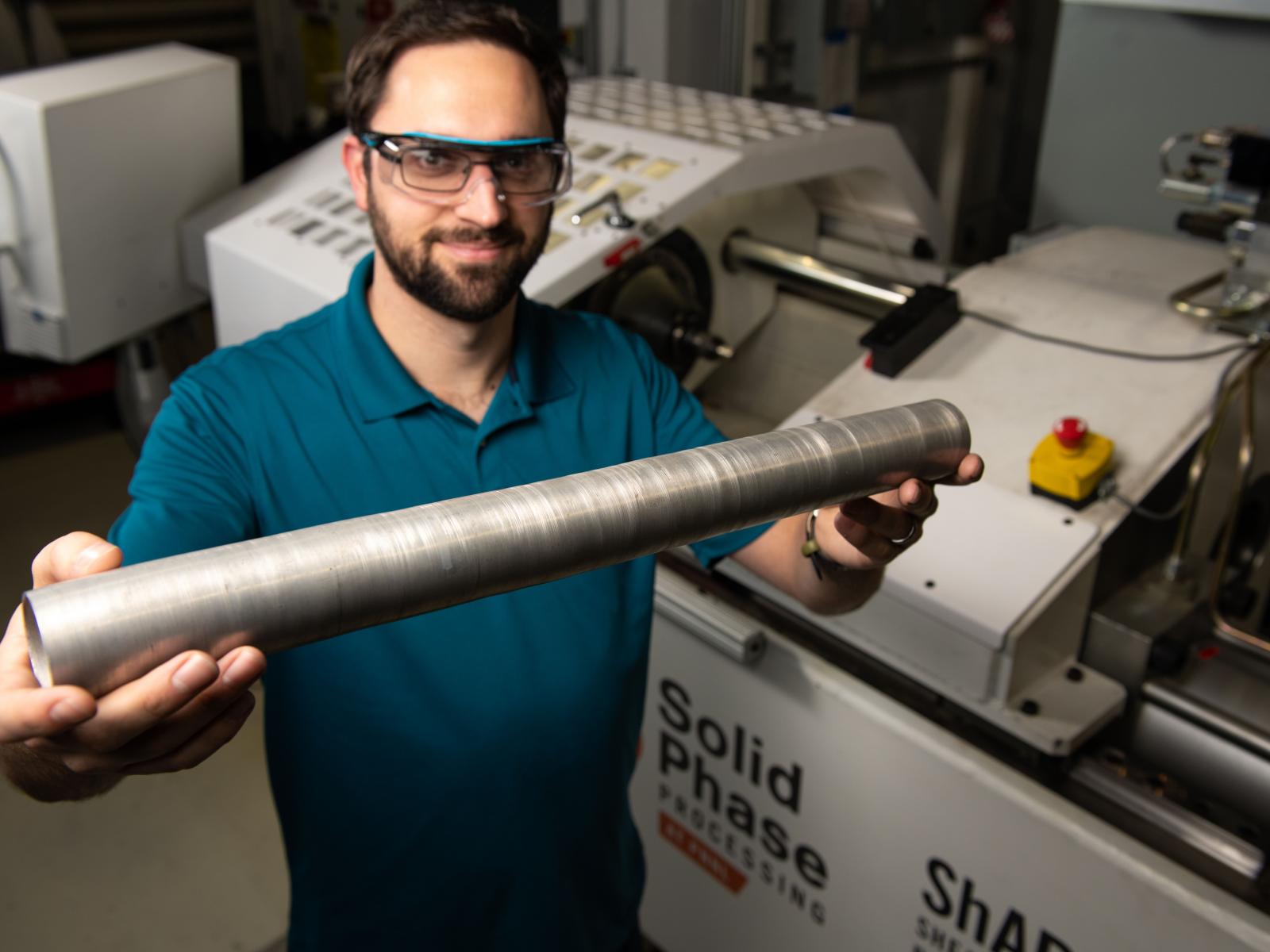

PNNL mechanical engineer Brandon Taysom holds a tube manufactured using PNNL’s patented Shear Assisted Processing and Extrusion process—known as ShAPE™—which makes it possible to produce lighter weight vehicle components and offers a less energy-intensive alternative to conventional manufacturing methods.

(Photo by Andrea Starr | Pacific Northwest National Laboratory)

With Memorial Day right around the corner, people are beginning to plan family road trips.

They might be choosing destinations, charting routes and calculating expenses.

Meanwhile, at the Department of Energy’s Pacific Northwest National Laboratory, researchers are developing technologies that improve fuel efficiency and lessen environmental impacts while also making your trip more affordable and convenient.

Scientists and engineers at PNNL are applying their expertise in materials science, energy storage and computing to create an integrated approach to sustainable transportation solutions.

Their efforts align with national priorities to reduce greenhouse gas emissions and deploy clean energy technologies.

Since transportation is the nation’s largest contributor of greenhouse gas emissions, their advancements will help the United States reach its goal to achieve net-zero emissions by 2050.

An award-winning PNNL technology is being used to reduce the weight of vehicles, which would allow you to travel farther before needing to refill the gas tank or recharge the battery. This technology is called Shear Assisted Processing and Extrusion, or ShAPE™.

This patented, energy-efficient manufacturing method makes it possible to use aluminum alloys to produce lighter and stronger vehicle components while speeding the manufacturing process and lowering production costs.

ShAPE™ also reduces greenhouse gas emissions associated with producing vehicle components by more than 90 percent because it does not require virgin aluminum.

Researchers at PNNL are addressing the process engineering and underlying materials science challenges that enable industrial production of automotive components from aluminum scrap, such as rain gutters.

Based on these advancements, Magna International, a leading producer of automotive supplies, is licensing ShAPE™ to manufacture battery trays for electric vehicles directly from scrap.

Other research at PNNL focused on batteries may help speed the adoption of electric vehicles.

Innovative researchers are helping to reduce the cost of batteries while increasing how far they can go between charges and how many times they can be recharged. Increasing the performance of electric vehicles and making them more affordable is key to enabling widespread availability and accessibility.

As the leader of DOE’s Battery 500 Consortium, PNNL works with other national laboratories, universities and industry to develop lithium-metal batteries that weigh less and hold more energy than today’s lithium-ion batteries.

As part of this collaboration, researchers are advancing the fundamental science related to electrode design, choice of electrolyte and the final materials integration to enable lithium-metal battery technology.

They also build and test prototypes, helping demonstrate the real-world viability of their solutions.

Shifting our focus from vehicles to their drivers, PNNL data scientists combined Uber driver data and other publicly available traffic data with the power of machine learning to develop a tool that can pinpoint traffic snarls in near real time.

The team used their tool, called TranSEC, to create a traffic congestion model of the 1,500-square-mile Los Angeles metropolitan area in a matter of minutes as opposed to the hours required by conventional methods.

TranSEC can be used in any urban area and allows traffic engineers to monitor and predict traffic patterns in new ways to help inform planning.

And once you get where you’re going, another PNNL technology seeks to reduce the frustration of finding a parking spot.

PNNL researchers and collaborators developed a simulation tool that can help municipalities understand and balance the competing demands for curb use, for example, parking, delivery and public transportation.

With a city-wide view, decision-makers could consider pricing, zoning, timing and availability to reallocate curb space throughout the day to reduce congestion.

At PNNL, researchers take a holistic approach to advancing sustainable transportation that will benefit the nation and the family road trip.

Unfortunately, it’s still up to you to deal with the inattentive spouse and whiny kids incessantly asking, “Are we there yet?”

Steven Ashby, director of Pacific Northwest National Laboratory, writes this column monthly. To read previous Director's Columns, please visit our Director's Column Archive.

Published: May 23, 2022