Predictive Simulation of Foam Delivery Technology (FDT)

Foam is a non-Newtonian fluid and hence its dynamic viscosity varies with flow rate. Foam is not stable and foam bubbles will eventually break. The properties of foam are also dependent on surfactant type and concentration. Consequently, existing flow simulators may not be directly used to model foam flow in porous media without correctly describing these processes.

Foam has been shown to improve reservoir sweep efficiency in gas-injection enhanced oil recovery (EOR) projects. However, the foam bubble size for DVZ remediation is different than from that used for EOR. EOR uses large polyherdral foams which have a tendency to break in porous subsurface environments, resulting in release of the associated water and reactant. Alternatively, micron-sized foam provides enhanced stability, amendment delivery and control than was often used for EOR.

Because foam delivery has been used in the petroleum industry to enhance oil recovery since the 1960s, several models of foam transport in porous media have been developed for application to EOR, but these approaches have been developed for initially saturated conditions. To date, the research of the transport of microfoam in porous media is very limited especially under initially unsaturated conditions. Hence, previous modeling efforts for foam in subsurface media provide a starting point, but because vadose zone sediments are unsaturated model development may differ from existing approaches.

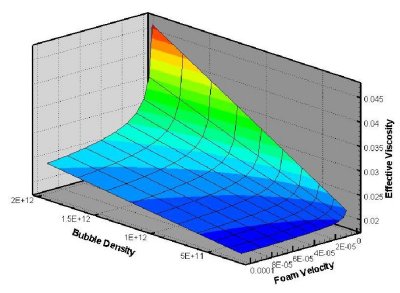

The transport of foam in porous media is complicated in that the number of bubbles present governs flow characteristics such as viscosity, relative permeability, fluid distribution, and interactions between fluids. During transport, foam destruction and formation occur. The net result of the two processes determines the foam texture (i.e., bubble density). Some of the foam may be trapped during transport. According to the impacts of the aqueous and gas flow rates, foam flow generally has two regimes — weak and strong foam. There is also a minimum pressure gradient to initiate foam flow and a critical capillary pressure for foam to be sustained. Similar to other fluids, the transport of foam is described by Darcy's law with the exception that the foam viscosity is variable.

Three major approaches to modeling foam transport in porous media are the empirical, semi-empirical, and mechanistic methods. Mechanistic approaches can be complete in principle but may be difficult for obtaining reliable parameters, whereas empirical and semi-empirical approaches can be limited by the detail used to describe foam rheology and mobility. Mechanistic approaches include the bubble population-balance model, the network/percolation theory, the catastrophe theory, and the filtration theory. All these methods were developed for modeling polyhedral foam, with the exception that the filtration theory method was developed for modeling ball foam (microfoam). Due to the limited understanding of microfoam transport in initially unsaturated soils, we will first develop the modeling capability based on the empirical approach and the filtration theory without considering bubble dynamics. During the course of the project, as we know more about the variation of bubble size and stability though experiments, the simulation capability will then be extended by including bubble dynamics. It is suspected that microfoam will become coarser and behaves like regular foam when foam transport lasts beyond the time of bubble stability. In this case, the modeling approaches such as the bubble population-balance and the catastrophe theory for regular foam may be considered to model the transport process.

The simulation capability of foam transport in porous media can predict the transport of foam and other common fluids such as water and air. Additionally, it can also be used to predict the transport of other non-Newtonian fluids and surfactant solution with variable properties used for soil flushing. The simulation capability can be used to investigate the impacts of different factors such as properties of surfactant, foam, and soil, and operation conditions on remediation effectiveness and efficiency. These results can be used to guide the selection of foam with the appropriate properties (e.g., bubble size, foam stability and quality). The simulator can be used for experiment design in the laboratory and in the field. It can be used to optimize field remediation implementation including foam injection rate, duration and location for high remediation effectiveness and efficiency.